Boeing's 787 in the spotlight after deadly Air India crash

Published in Business News

A Boeing 787 with at least 240 people on board crashed shortly after takeoff Thursday in the northwestern Indian city of Ahmedabad.

The Air India passenger plane bound for London crashed into a nearby medical college. The dead might include both passengers and those on the ground, the city police chief told reporters.

It’s too soon to know the cause of the crash. Regulators from India and the United States will investigate, and it could take months to fully understand what went wrong.

But the incident immediately renewed concerns about Boeing’s 787 Dreamliner, the jet maker’s smaller widebody plane. While the 787 has never before been involved in a fatal crash, it has been the subject of allegations about manufacturing quality.

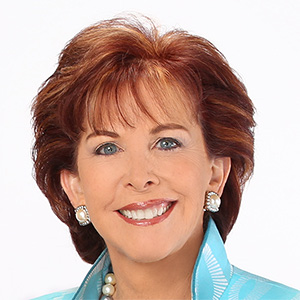

Campbell Wilson, the CEO of Air India, said the airline would continue to report timely information as soon as it could but “anything we report must be accurate and not speculative.”

“I know that there are many questions at this stage and I will not be able to answer all of them,” Wilson said in a statement posted on X. “Investigations will take time. But anything we can do now, we are doing.”

Boeing said in a statement that it is in contact with Air India and stands “ready to support them. Our thoughts are with the passengers, crew, first responders and all affected.”

Boeing launched the 787 Dreamliner in 2009 and now assembles the plane in its North Charleston, S.C., factory.

The 787 had never been in a crash before Thursday. But it has come under scrutiny for quality concerns, including in 2013 when Boeing briefly grounded the fleet because of a problem with lithium-ion batteries.

The plane that crashed Thursday first flew in 2013 and was delivered to Air India in January 2014, according to aviation analytics firm Cirium.

It was manufactured in Everett, according to Cirium, before Boeing consolidated 787 production in its South Carolina facility.

In 2020, Boeing found tiny gaps at the joins in the fuselage section in the 787, a flaw that could potentially weaken the structure of the fuselage. Boeing said at the time that the gaps did not pose an immediate safety concern, but the company largely stopped deliveries of that plane model for almost two years as it worked to correct the flaws.

Concerns about those gaps resurfaced last year when a whistleblower accused Boeing of failing to fix the problem and taking manufacturing shortcuts to increase production rates for the 787 and the 777. Sam Salehpour, a Boeing quality engineer, testified before Congress in April 2024, alleging that the company was “putting out defective airplanes.”

Boeing denied Salehpour’s allegations and told reporters it had made meticulous, time-consuming changes to the 787’s airframe to eliminate the gaps, with extensive testing overseen by the Federal Aviation Administration.

Earlier that year, Boeing 787 whistleblower John Barnett died by suicide in the midst of giving depositions alleging that Boeing had retaliated against him for complaints about quality lapses.

Separately, in May 2024, the FAA opened an investigation into Boeing’s 787 Dreamliner after the company disclosed that employees in South Carolina falsified inspection records.

Workers had not performed some inspections related to work done where the wings are joined to the fuselage body, despite records indicating the inspections had been complete, Boeing informed the FAA.

Those allegations surfaced when Boeing was facing heightened regulatory scrutiny following a near-catastrophic incident on its 737 Max 9 plane. In January 2024, a panel flew off an Alaska Airlines 737 Max midflight near Portland, leaving a gaping hole in the side of the plane.

Boeing is also still recovering from the fallout of two fatal 737 Max crashes in 2018 and 2019, which killed 346 people.

Boeing’s stock price fell 8% Thursday morning after news of the crash.

©2025 The Seattle Times. Visit seattletimes.com. Distributed by Tribune Content Agency, LLC.

Comments